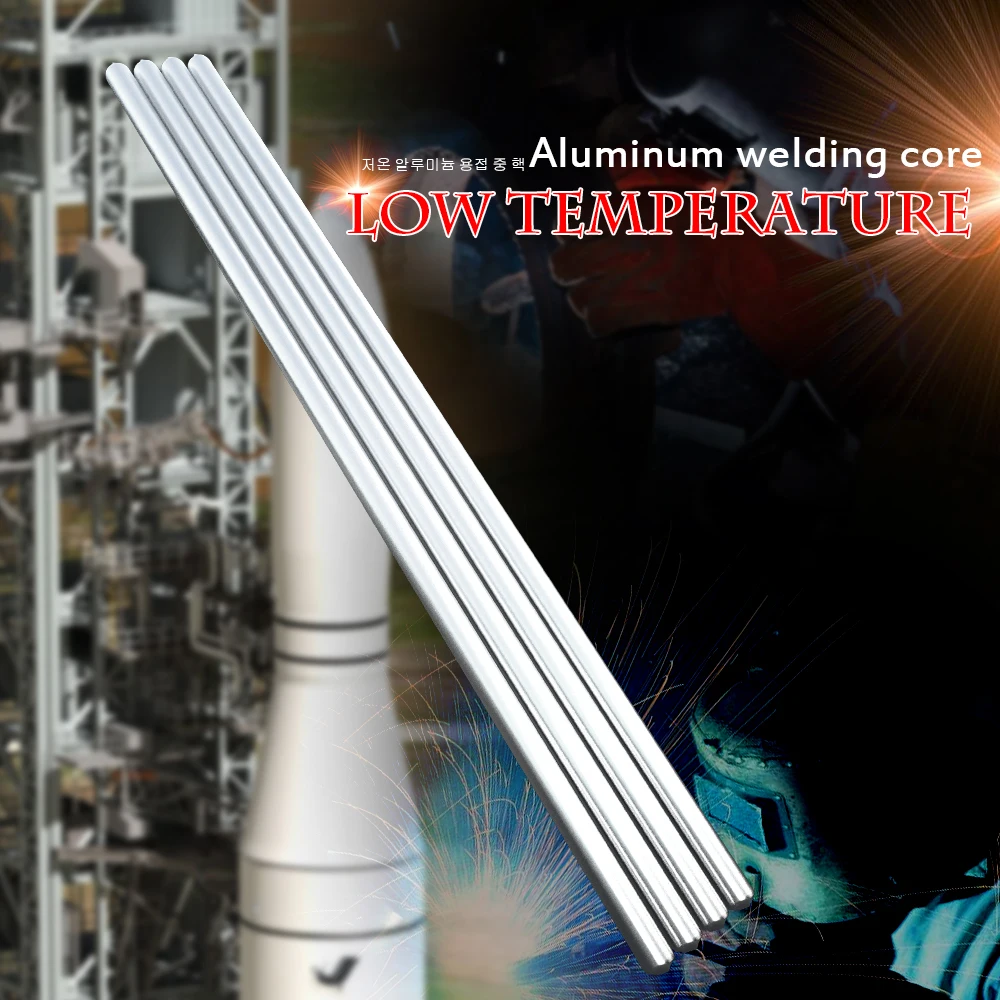

Aluminium Welding Rods

Aluminium welding rods are a pure aluminium welding wire with an aluminium content greater than 99.7%. It is a kind of universal welding material with wide application.

Features:

Great Welding Effect – With full & smooth welding effect because of internal powder. With low melting point(647℃~658℃), great weldability and corrosion resistance, high thermal conductivity, high electric conductivity and excellent processing performance.

No Need Solder Powder – You don’t have to use other flux powder with aluminium alloy as the welding core and coating as the salt base. Very convenient and easy to weld.

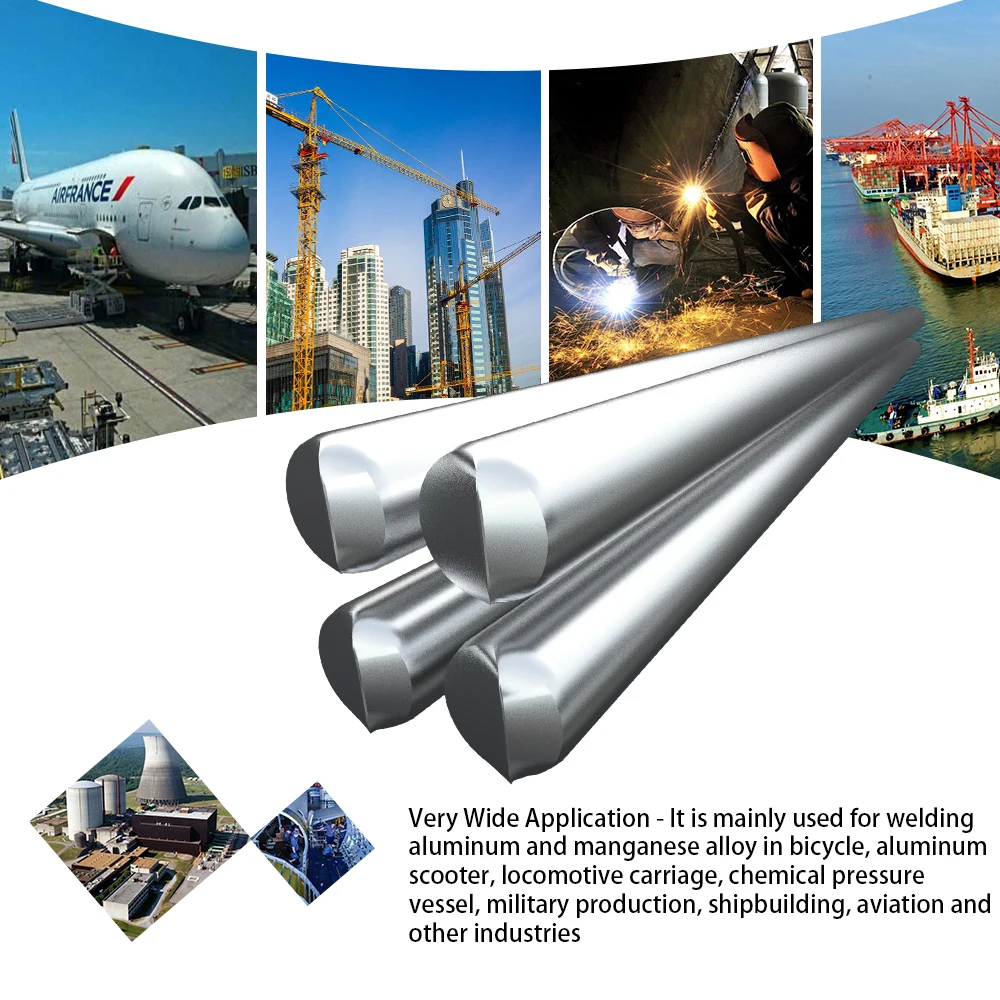

Widely Use In Life – Suitable for welding or surfacing welding alloy with high strength, good forge ability & good corrosion resistance.

Very Wide Application – It is mainly used for argon arc welding and filling material for pure aluminium, connection with aluminium bus and guide rod of electrolytic aluminium plant and electric power, chemistry, food and so on.

Lightweight, small volume, very easy to bend and carry.

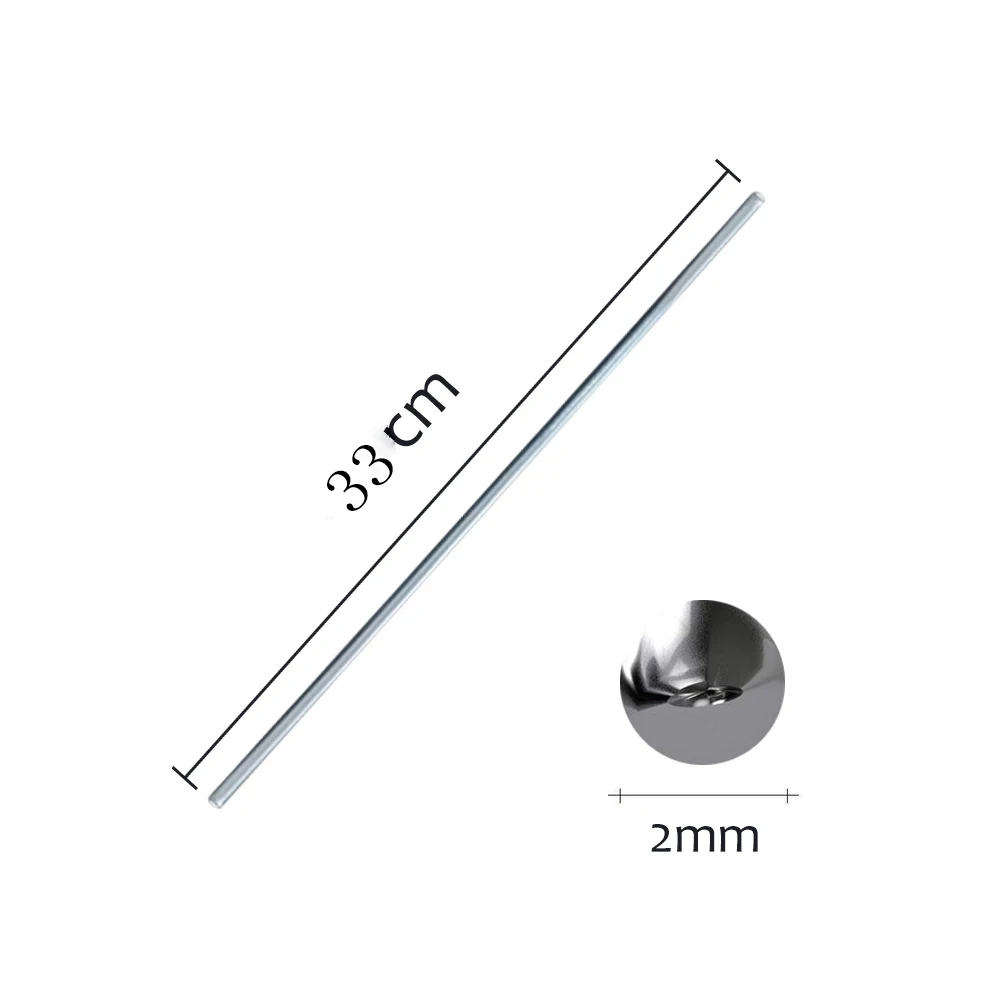

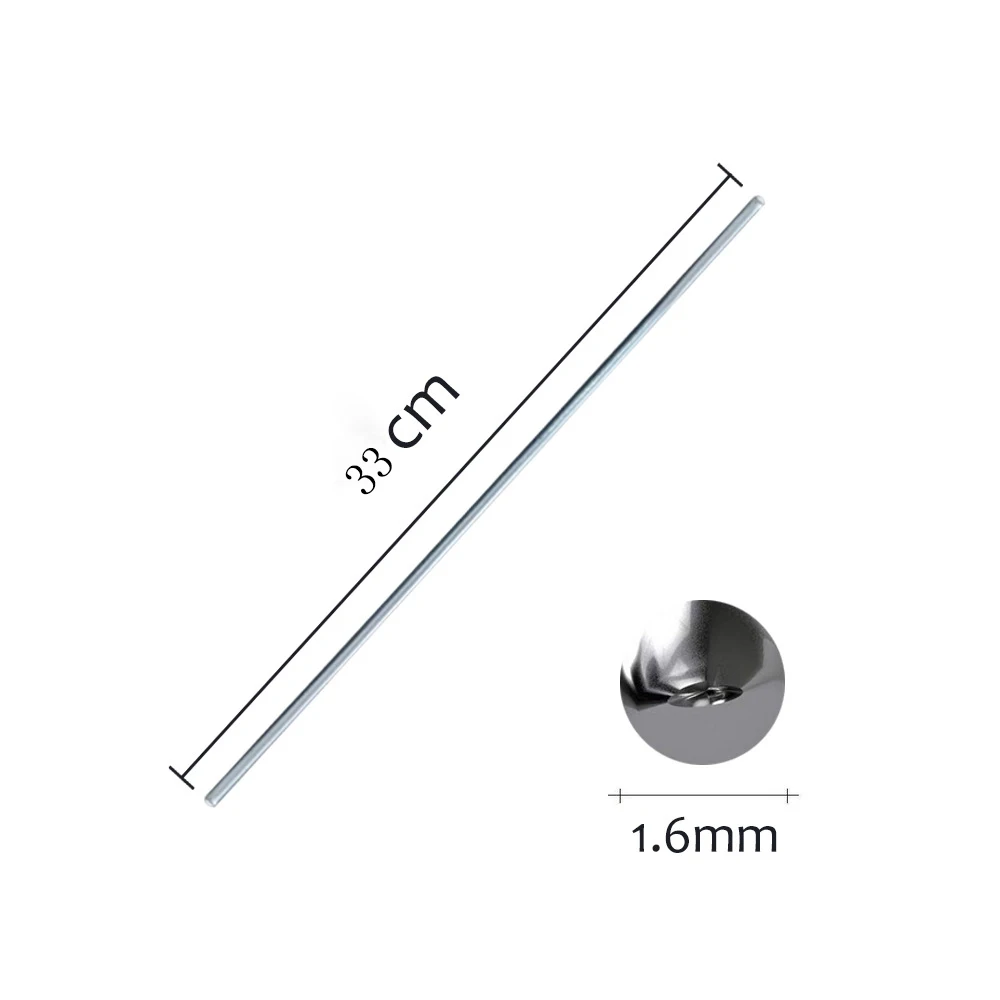

Specification:

Material: Aluminum

Melting Point: 647℃~658℃

Recommended for welding or brazing aluminum alloy: 1060, 1350, 3003, 3004, 3005, 5005, 5050, 6053, 6061, 6951, 7005, and cast alloys 710.0 and 711.0

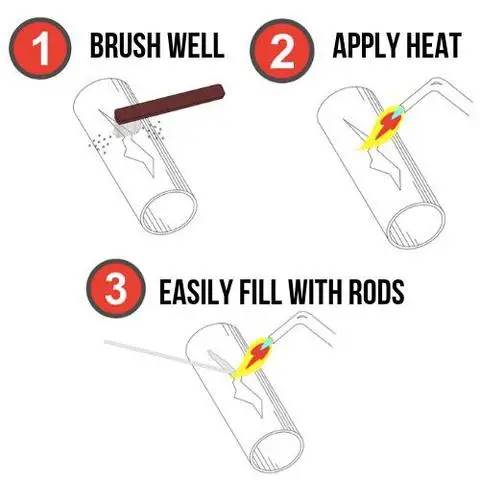

How to Use:

Step 1: Clean and polish the physical surface.

Step 2: Heat the surface of the base material, until the temperature of the wire to the operating temperature of 380℃~400℃, so you can rely on the parent metal heat transfer welding wire to form welds, should not use the flame to burn wire, When the surface temperature of the base metal is sufficient, the wire can flow well and penetrate into the metal capillary.

Step 3: When repairing thin aluminium, as long as the aluminium base metal heated to the appropriate working temperature, and then use the wire back and forth friction melting to form a weld, only with a metal brush melt welding wire to weld at the weld.

Step 4: Use propane gas to weld small object, use industrial gas or induction heating device to heat and weld big object, natural slow cooling after welding.

Application in Life:

Can be used for a variety of heat sources, such as propane, oxy-acetylene and so on. Low-temperature aluminium welding wire can weld almost all white metal, including aluminium, aluminium, cast aluminium, aluminium alloy and dissimilar welding between the above-mentioned metals, even for serious corrosion or oil pollution of white metal, and even that the aluminium alloy that cannot be repaired can be repaired. Applicable to the primary welding operator all-round welding, only a small heating device, after welding the weld strength is generally higher than the strength of the base metal itself, can understand the gas welding operation.

NOTE:

1. The surface of the base metal must be clean.

2. The base metal temperature to reach 400 degrees, including the process of welding the base metal temperature should be maintained at 400℃, and the temperature can be high or low.

Recommendation from customers:

Good product and fast shipping – Forest City, United States

Value for money – Ashburn, United States

The products are packed well. Recommend store – Dublin, Ireland

All good thanks

Not tested still

Good value for money

ok product.

Everything is fine

All it's Ok! Recommended!

Goods as described.

Goods arrived ok. You are required to move quickly and at the correct temperature to create a good job.

well packed and protected, need to try

Fast delivery. All as described

Still need to be used but good thanks

Delivered quickly

very very fast delivery 10 days GR

Arrived quickly, tried until there was nothing I could try further

In appearance, everything is quality.

Over on aluminum firm also fit on copper.

Shipping norms.

The goods came safely, packed in a proper package. Checked in the work, pasted well, the flux is enough, for a good result you need to warm up the detail very well. Everything is super, I recommend to buy

The complete set is declared

Hello I received my order works perfectly, fast shipping as well as delivery professional store recommended

perfect as described, thank you.

Good Aluminium Welding Rods

Flux is present

as described

In the Urals in 9 days from Moscow. the thin-walled aluminum pipe was round and it was easy and simple. 2mm square did not work out apparently little heated. Although on the side wall to attack solder could. I will add