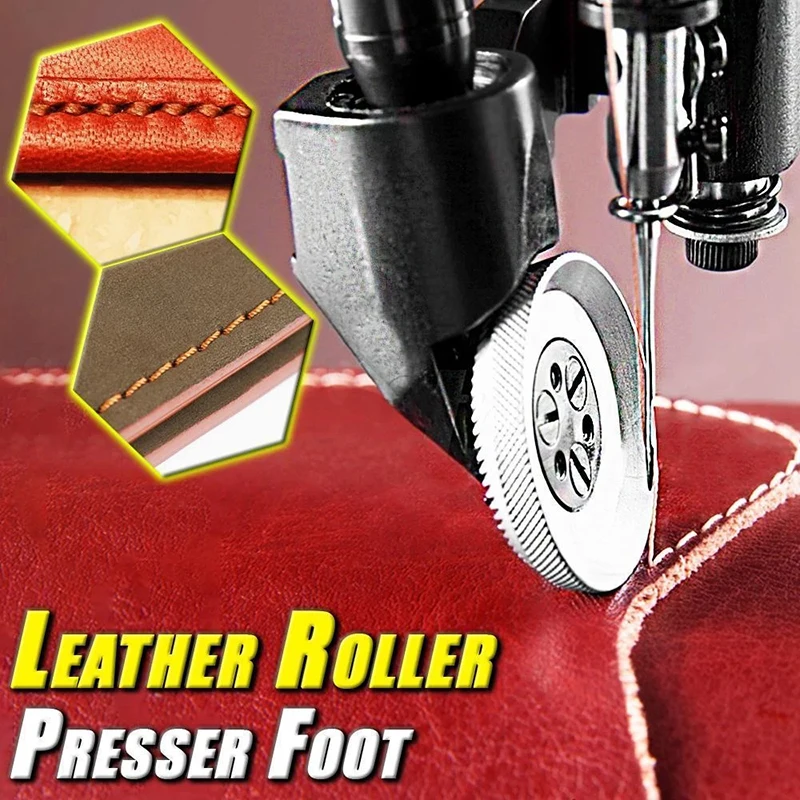

Leather Roller Presser Foot

This Leather Roller Presser Foot gives you more control and causes less friction between the foot and feed the dog while sewing or quilting on leather, denim, fur, suede, synthetics and napped or piled fabrics.

This Leather Roller Presser Foot is effective for preventing fabric (stretchy materials like jerseys and knitted fabrics or hard-to-feed materials like leather or vinyl) from slipping or puckering because the presser foot rotates to feed the upper layer together with the lower layer without slippage, so the upper layer and lower layer are fed simultaneously.

FEATURES:

Application for High Shank Sewing Machine including Singer 17U / 18U sewing machine / 810 high-head machine / flat machine, SINGER, JUKI, CONSEW, ECONOSEW, ARTISAN, MITSUBISHI, TAIKO, JANOME 1600P, BROTHER, KENMORE, BERNINA, and all other comparable style machines.

Use for laminated Fabrics, foam rubber, nylon, plastics & leather.

Simple installation, easy to use, necessary parts for industrial sewing machines.

Reasonable size, lightweight, easy to store and carry.

Made of high-quality steel material, anti-rust, and high hardness.

HOW TO USE:

Attach Leather Roller Presser Foot to the machine; adjust the needle position to the far left to sit next to the wheel of the foot.

Place the trim on the right side of the fabric edge, aligning the flange of the trim with the raw edge of the fabric. Stitch the trim to the fabric, sewing next to the trim.

Place the second piece of fabric right side down, aligning the raw edges of both fabrics. Using the same settings as above, stitch through all layers, on top of the first stitching.