A4 Thermal Laminating Machine

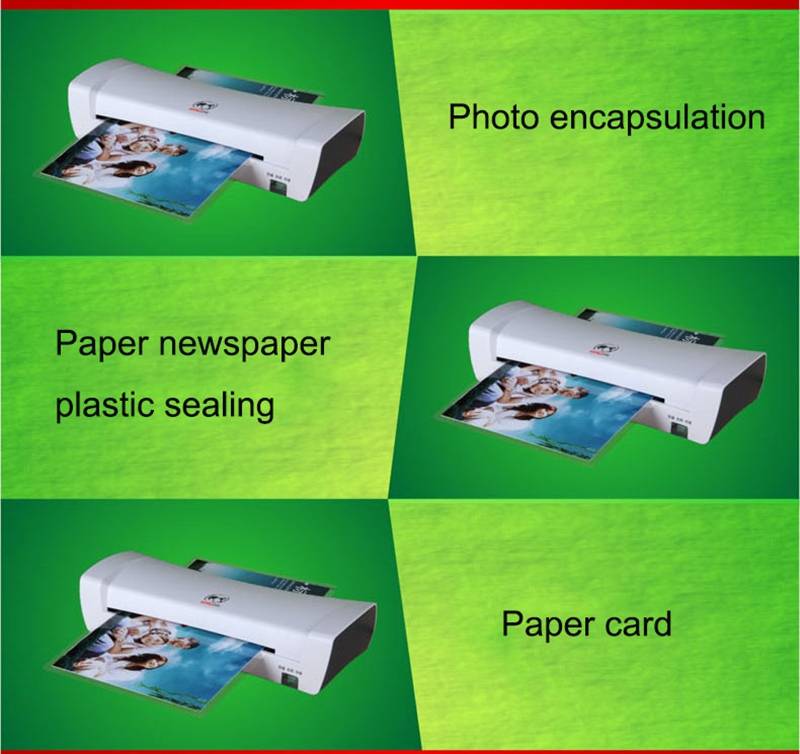

As you know, old photos are on paper, which tends to tear after some time. Don’t worry! Our A4 Thermal laminating machine will keep your paper, document, and photo fresh. The laminator only takes 2-4 minutes to warm up. Such a fast speed of 280mm/min can improve your work efficiency, you just need to take about 35 seconds to imprint an A4 paper. With 2 roller designs, the laminating machine ensures a smoother and faster lamination, which prevents jam, bent, wrinkles, or folded corners when laminating. ABS can stop and fix jammed paper in seconds. Hot and cold laminator provides you different pressure requirements for photos, documents, specimen, business card, menu, clipping, stamp, etc. Get it now!

Preheat time: 2-4mins

Laminating film thickness: 80-125mic

Max width of paper: 230mm

Max laminating thickness: 0.5mm

Power: AC220-240V, 220w

Machine size: 352x126x75mm

Package Included:

1 x A4 Thermal Laminating Machine

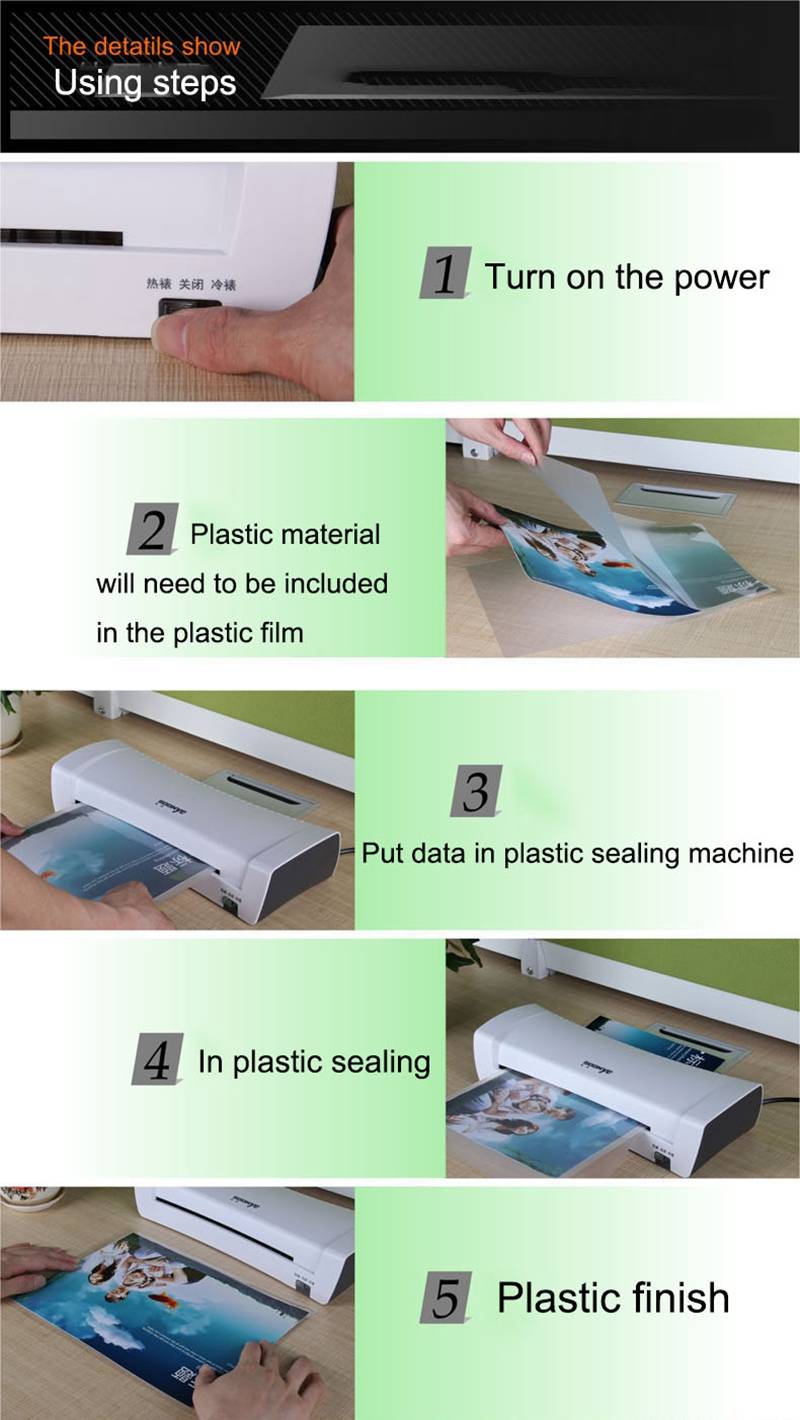

Use steps:

1, put the plastic press on the platform and connect the power supply.

2, switch the plastic switch to the left hot mounting position, and the machine enters the heating state.

3, put the plastic object into the middle of the 2 layer of plastic film, and the distance is symmetrical as far as possible.

After 4 or 21 minutes, the machine is heated, the green light is on, the film clipped with the paper is put into the paper mouth, and the end of the edge pressing is first put into the paper mouth.

5. After the paper placed in the film clip is put in, the machine automatically passes through the plastic. The direction of the paper outlet ensures that there is enough space between the paper outlet and the paper outlet. Let it extend automatically until it is finished.

6. Overplasticization is completed. Please remove the over-plasticized object immediately and place it on the platform. The over-plasticized object can be pressed on a book or an upright object to make the over-plasticized object smoother and smoother.

Matters needing attention:

1 when hot mounting is needed, switch the switch to the hot mounting position and wait for the green light to light.

2 the thickness of the plastic film should be consistent with the specifications of the machine (80 1 1 25mic).

3 put the plastic material in the middle of the plastic film, and make it as neat as possible.

4 please send one end of the plastic film to the inlet of the plasticizing machine.

Do not touch the heat sink and the top cover of the machine with your hands when the machine is working, so as not to burn your hands, and do not cover any objects on the machine at the same time.

6 turn off the power when not in use, while unplugging the power plug, do not cut off the power when it is over plastic.

7 the basin is suitable for indoor or cool and safe environment.

Common faults:

If plastic film can not be sealed, please check whether the thickness of plastic film is within 125 mic, or if the thickness of paper film is more than 0.smm. If plastic film is stuck in the machine, or there are serious problems such as bad blank holder and air bubbles. Please contact our after-sales department in time. Assist on-site solution or after-sales. Rework treatment

Reminder:

When the superplasticity is less than A4 paper and other paper, please try to place the Superplasticity in the middle of the machine, the effect will be better.

Special reminder:

Every time the hot mounting is finished, the hot mounting state should be changed to the cold mounting state, so that the machine can run in the cold mounting state for 5-10 minutes and then dial to the closed position, which can prolong the service life of the machine.

Thermal overcast:

Dial to the left hot mounting position, that is, enter the heating state.

Hot mounting: refers to the machine heating using two layers of hot mounting film (also known as superplastic film) to seal the plastic work. Generally, there are 2-3 mm edge sealing around. After the switch is set to hot mounting, the machine will be heated for 2-4 minutes and the green light will be turned on, then the glue will be passed.

Cold over plastic:

Dial to the right cold mounting position, that is, enter the cold mounting state.

Cold mounting: It means that the machine directly uses one-sided viscous cold mounting film without heating to perform the pressing work. It is generally used on smooth surface such as photographic paper and copperplate paper.

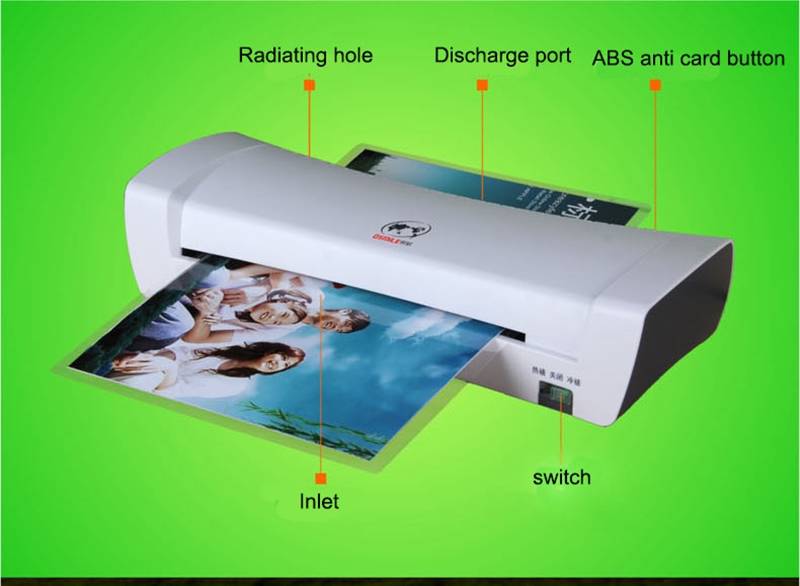

ABS anti card key function description:

When using the machine, due to improper operation: (for example: paper skewed, temperature did not reach the paper, and put into the object that can not be superplastic), resulting in machine sticker, found a similar situation. Should immediately move the ABS anti-card button to the left, while pulling the superplastic object out.

Rubber roller number: 2 axis

Preheating time: 2-4min

Glue thickness: 80-125mic

Maximum paper width: 230mm

Maximum adhesive thickness: 0.5mm

Voltage: AC 220-240V

Power: 220W

all good

OK!!!

product is well packaged and works great

Ok

Good product